Client Details

Services Provided

Project Timeline

Project Overview

Roborian’s team conducted an in-depth innovation assessment to understand the client’s current operations, pain points, and opportunities for improvement. The assessment involved collaborating closely with the client’s management team, conducting interviews with key stakeholders, and analyzing existing processes and systems.

During the innovation assessment, Roborian identified several areas where Intelligent Automation technologies could significantly benefit the food manufacturing company. These included production line optimization, supply chain management, inventory control, and quality assurance.

The Back Story

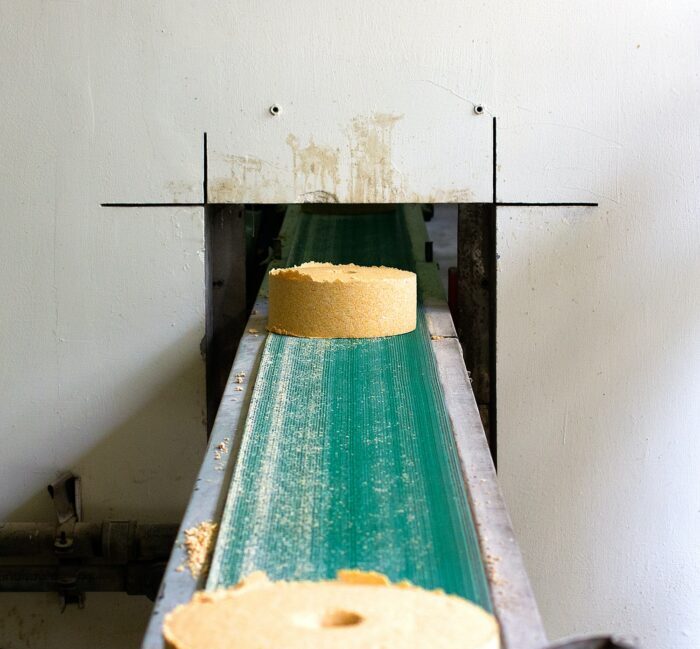

Roborian partnered with a food manufacturing company, a leading player in the industry known for its high-quality products and extensive distribution network. The company was looking to enhance its operational efficiency, streamline processes, and leverage innovative technologies to stay ahead in a competitive market.

The Solution

Intelligent Automation

- Production Line Optimization:

Roborian implemented a robotic process automation (RPA) solution to automate repetitive and time-consuming tasks on the production line. By integrating intelligent automation into the manufacturing process, the company achieved higher accuracy, improved cycle times, and reduced operational costs. The RPA solution allowed for seamless coordination between machines and employees, enhancing overall productivity and reducing human error. - Supply Chain Management:

To optimize the client’s supply chain management, Roborian developed a custom software solution that leveraged AI technologies. The solution incorporated machine learning algorithms to forecast demand accurately, optimize inventory levels, and streamline logistics and distribution. By implementing this system, the food manufacturing company experienced reduced stockouts, minimized waste, and improved delivery accuracy, resulting in enhanced customer satisfaction and cost savings. - Quality Assurance:

Roborian implemented computer vision and AI technologies to enhance the client’s quality assurance processes. By deploying visual recognition algorithms, the system automatically inspected products on the production line, identifying defects and ensuring compliance with strict quality standards. This solution eliminated the need for manual inspection, reducing human error and increasing production efficiency while maintaining consistent quality across all products.